This is a continuation of my previous post. In this post, I will complete the window up to the point of dry-fitting. When we left off, we had four 25” long 2”x1 1/4” pieces of wood.

After cutting to size and marking which pieces were to be used for rails and which for stiles, the next step is to mark the tenons on the rails. When doing a mortise and tenon joint in a corner joint, such as a window or picture frame, it is important to cut an additional shoulder in the tenon. This is referred to as a haunched tenon. If you don’t do this, then the entire side of the tenon will be visible on the outside edge of the window, which reduces strength and looks bad.

Here are the haunched shoulders marked on the rails:

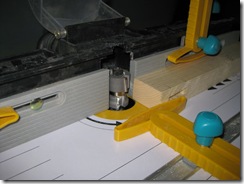

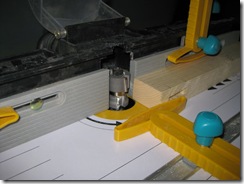

Now, we’ll setup the table saw for cutting the tenons. Here is my table saw with the supplied miter attachment:

We remove the miter attachment and put in my home-made t-groove track attachment:

We remove the miter attachment and put in my home-made t-groove track attachment:

This is a 28” x 8” 3/4” thick piece of MDF left over from a previous kitchen update. I plunge-routed the groove for the t-groove track and two bolts. The t-groove piece I bought from a local tool shop. Now we mount the tenon jig:

This is a 28” x 8” 3/4” thick piece of MDF left over from a previous kitchen update. I plunge-routed the groove for the t-groove track and two bolts. The t-groove piece I bought from a local tool shop. Now we mount the tenon jig:

Here is a pic of the tenon jig showing how it holds your rails:

Here is a pic of the tenon jig showing how it holds your rails:

This would be an incredibly tricky cut to do without a jig. The jig has settings that allow you to align everything so you get precise shoulder cuts. Here are the rails with the shoulders cut:

This would be an incredibly tricky cut to do without a jig. The jig has settings that allow you to align everything so you get precise shoulder cuts. Here are the rails with the shoulders cut:

You can see how poor my saw blade is. I need to get the new finishing blade on soon. Next we mount the rails back in the jig to cut the haunched shoulder:

You can see how poor my saw blade is. I need to get the new finishing blade on soon. Next we mount the rails back in the jig to cut the haunched shoulder:

Now, we remove the jig, and setup the blade to remove the shoulder material.

Typically, some clean-up will need to be done once the tenons are cut. You can use a rasp, wood file, or sharp chisel to clean up your edges. I will wait to do that until after my mortises are cut so that I don’t remove too much material.

Typically, some clean-up will need to be done once the tenons are cut. You can use a rasp, wood file, or sharp chisel to clean up your edges. I will wait to do that until after my mortises are cut so that I don’t remove too much material.

Now, we’ll mark the mortises. You can assume your tenons are perfectly situated on the rails (not likely), or you can mark the mortises using the tenons (which I did). Here are the mortises marked:

Using the mortiser, I position the fence to accurately cut the mortise holes. The mortiser will make a 1/4” x 1/4” square hole each time it plunges, so you have to move the workpiece along until the mortise is cut. It’s a good idea to cut the two ends first with a scrap piece of wood beneath so that you avoid tear-out on the bottom with the through mortise. Then, you can plunge the in-between holes most of the way through, flip the work piece over and plunge from the other side. This gives a cleaner mortise. Here are the mortises:

Using the mortiser, I position the fence to accurately cut the mortise holes. The mortiser will make a 1/4” x 1/4” square hole each time it plunges, so you have to move the workpiece along until the mortise is cut. It’s a good idea to cut the two ends first with a scrap piece of wood beneath so that you avoid tear-out on the bottom with the through mortise. Then, you can plunge the in-between holes most of the way through, flip the work piece over and plunge from the other side. This gives a cleaner mortise. Here are the mortises:

Now, we do the first dry fit. None of the edges have been routed yet, but this will allow you to adjust your mortises and tenons slightly (chisel, file, rasp) to get a good fit. You want a tight, but not overly tight fit, because you want space for glue and the wood will expand with the glue. Here’s the test fit:

Now, we do the first dry fit. None of the edges have been routed yet, but this will allow you to adjust your mortises and tenons slightly (chisel, file, rasp) to get a good fit. You want a tight, but not overly tight fit, because you want space for glue and the wood will expand with the glue. Here’s the test fit:

Here you can see one of the through tenons:

Here you can see one of the through tenons:

Now, we move onto routing the edges. We start by using the coping bit, which looks like:

Now, we move onto routing the edges. We start by using the coping bit, which looks like:

You align the height so that the top of the bit is just touching your tenon, with the face side down. You then align the fence so that it will cut 1/4” into the wood, like so:

You align the height so that the top of the bit is just touching your tenon, with the face side down. You then align the fence so that it will cut 1/4” into the wood, like so:

After routing the coping cut on all 4 ends of the rails, you mount the sticking bit, which looks like:

After routing the coping cut on all 4 ends of the rails, you mount the sticking bit, which looks like:

You align the bit so that the sticking cut will have the same reveal and the 1/4” part in the middle lines up with the coped rail edges. The fence aligns with the front of the bearing in the middle of the bit. You then route all four inside edges (face side down).

You align the bit so that the sticking cut will have the same reveal and the 1/4” part in the middle lines up with the coped rail edges. The fence aligns with the front of the bearing in the middle of the bit. You then route all four inside edges (face side down).

Once that’s done, you can do another dry-fit. You’ll note that the tenons come through further than the outside edge of the window. This is because of the 0.5” overlap with the cope and stick cuts on the edges. You can use a small saw or a table-saw (very carefully) to remove these. It’s better to have your tenons come out the side and trim them, then to have them too short.

Here is the assembled window:

Next up is doing minor tweaks to clean up where the pieces fit together, removing the excess wood from the tenons, then gluing, priming, and glazing. Some of our windows have pinned tenons, meaning that a piece of wood or nail is driven into one of the window frame faces through the tenon. This gives the joint even greater strength. I’m not sure if we’ll do this or not with these smaller storms.

Next up is doing minor tweaks to clean up where the pieces fit together, removing the excess wood from the tenons, then gluing, priming, and glazing. Some of our windows have pinned tenons, meaning that a piece of wood or nail is driven into one of the window frame faces through the tenon. This gives the joint even greater strength. I’m not sure if we’ll do this or not with these smaller storms.

I hope I haven’t bored too many of you. I struggled to find good instructions on the web for building the windows, and thought it might be useful for others if I tried to do a detailed step-by-step.

If you’re curious of the work effort involved, I spent 3-4 hours ripping the wood to the size I needed (I’m very slow when I have to use my table-saw without the guard), 2 hours doing the tenons, an hour to make the mortises, and another hour to do the routing of cope and stick cuts. So, 8 hours for one window. I think this time could be reduced by buying pre-milled wood in the basic thickness/width you need it, and doing more than one window at a time at each step, minimizing set-up and changing/aligning bits. I think the effort is worth it though. The end result is a strong, well-made window. The tools will pay for themselves very quickly as well, given the cost of replacement windows.

Thank you for sharing this. It will help on that day that I eventually get around to making storm windows.

ReplyDeleteFrom experience, I will say that good saw blades (and router bits) make all of the difference. With but one exception, I've had especially good luck with Freud's offerings, though there are other good companies. The one exception was their "glue line rip" blade which was not bad, but merely underwhelming - I think that was due to an underpowered table saw.

Do continue to take a long time when using a table saw without a blade guard. Trust me - this is experience speaking. It's too easy to try to work faster, with the inevitable bad results.

You'll be surprised how much strength is gained when you glue the pieces together, especially with modern wood glues. While I haven't worked with wood windows much (other than as stretchers for canvas (for painting)) I've worked with other things, like chairs, where the object seemed as flimsy as could be, but with the addition of some glue into the joints (and the requisite clamping), the object became quite solid. This is also a good way of making Ikea furniture much more durable.

Finally (almost done rambling!), with projects like this, there's a lot to be said for making the workpiece a bit too big and then finishing it to fit. A belt sander can remove that extra little bit of material that keeps the window from fitting right and can be done in a reasonably straight line, if one is careful. Even a random obital sander can do the trick. A hand plane will make the job easier, but a good hand plane costs as much as your table saw.

Christopher,

ReplyDeleteI agree, Freud products are great. I considered getting their sash window bits, but the max thickness for the sash frames is 1 3/8", and most of our windows are 1 3/4" thick. So, I went with the Amana bits instead, which are still highly rated. I do need to get the new saw blade on though for clean rips and cross-cuts.

I know the glue will help with strength, but eventually glue will fail, so I wanted the M/T joints for the inherent strength that will last. I did buy the weather-rated wood glue, which will help with longevity.

And with regards to the sizing, I didn't want to trim much using a plane, or sander, as I plan to use bronze strip weatherstripping. So, I knew that as long as I was within 1/8" in dimensions, I'd be fine. I'll post more on the weatherstripping when it arrives (I'm ordering it online).

As always, thanks for the feedback. Rambling comments that give good advice are definitely appreciated and welcome.

So how many window do you have to replace?

ReplyDeleteFor now (meaning this year), we have 9 (possibly 10) storm windows to make. The largest is a 3'x5' 4-lite.

ReplyDeleteThere are many other storm windows that need reglazing either due to broken glass, or deteriorated glazing compound. I can't remember the count for those, but I think it's in the range of 27 storms, the largest of which is probably 3.5'x7' 6-lite.

Once we have properly fitted, properly glazed storm windows, all the of the original double-hung windows need to be reglazed, most need new sash cords, and new paint. I'd like to also install bronze strip weatherstripping, and there's a few that are in such bad condition that I'll either have to build replacements or use a lot of wood epoxy to replace missing wood or severely checked wood.

Long term, probably in the range of 3-5 years, we'd like to make new wood casement windows to take the place of some PVC windows that were installed on the front and one side of the house about 15 years ago. I think there are around 19 of those, plus matching storms, with some transoms for the main floor front windows.

So, lots of window building/repair to do.

BTW, after reading your blog, I counted our doors, I think we have 39 (if you include some in the basement separating various areas of unfinished space). I think we have 56 windows in total, but I'll have to recount.

Hi, Did you design the windows yourself? Can you recommend a website or book on how to accomplish what you did? Thanks!

ReplyDeleteKudos to you for not going with plastic replacement windows, landfill junk imho. If you haven't seen this already, here's some info on how old windows are actually more energy efficient, economical, sustainable, longer lasting, higher quality & eco-effective than today's modern counterparts. http://www.windowrepair.com/research/research.html

ReplyDeleteWow, just came across these pages...thanks a ton!!! I am partners with nine other family members in my grandparent's home (we all agree and get along really well...heh). So, we have an 80 year old home with some windows that are in an advanced state of decay. I have maintained that new windows could be built/rebuilt while my father has said it would cost $100,000 to have new ones built by a window company. Looks like I have a new project to look forward to.

ReplyDeleteI bought a router bit like the one shown on this great site, but your instructions will allow me to make the replacement window I have needed to make for a few years.

ReplyDeleteI have found that mlcswoodworking.com has excellent router bits and very competitive prices.

Thank You

Gene

I thought this was very good, but I was wondering if you were going to circle back to it any time soon and finsish some of the topics that you didn't get to. I'd be particularly interested in how you do muntins.

ReplyDeleteI am interested in making new storm windows for a heritage home and was wondering where I would get the glass from?

ReplyDeleteperfect it took me so long to find this website now I can restore my windows! Thanks

ReplyDeleteThanks for the walk-thru! I have an 1859 house with 33"x77" 4 over 4 storms that are in rough shape. I called a shop specializing in exactly what I needed, their quote was $700 each, no glazing or finish. Times 24 windows. Ain't happening. I could probably lease CNC equipment for less than that and have windows down to .001" Think I will try your ideas first. Thanks again!

ReplyDelete